Reaping the quality we sow

Our statistical quality system draws on Six Sigma methodologies to understand the root causes of defects. So we can implant reliable controls.

Agrofoods global company

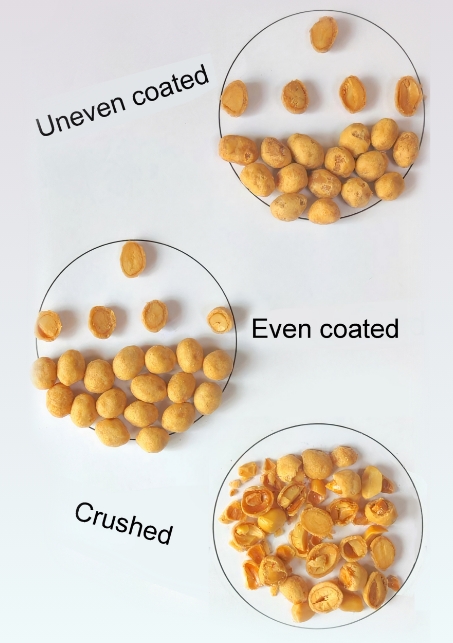

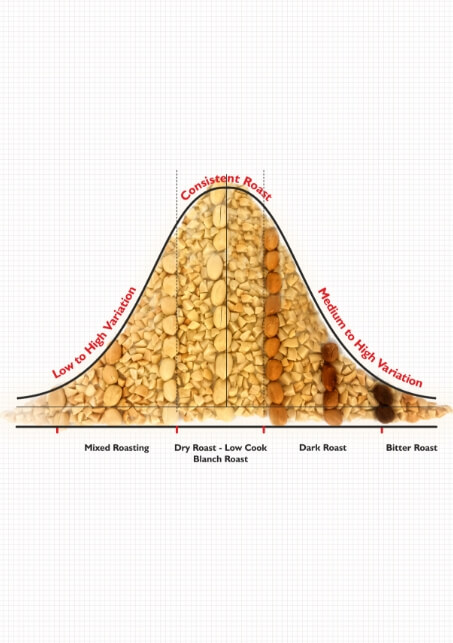

Image caption, describe the picture

Reducing grading variation

By avoiding nubs and mono shells in our grading system and processing based on five grade counts rather than ten, we improve the quality of our products

Maintaining consistent aflatoxin results

We draw on statistical controls to prevent aflatoxin growth, with combined subsampling and analytical variability estimates that iron out testing variations.

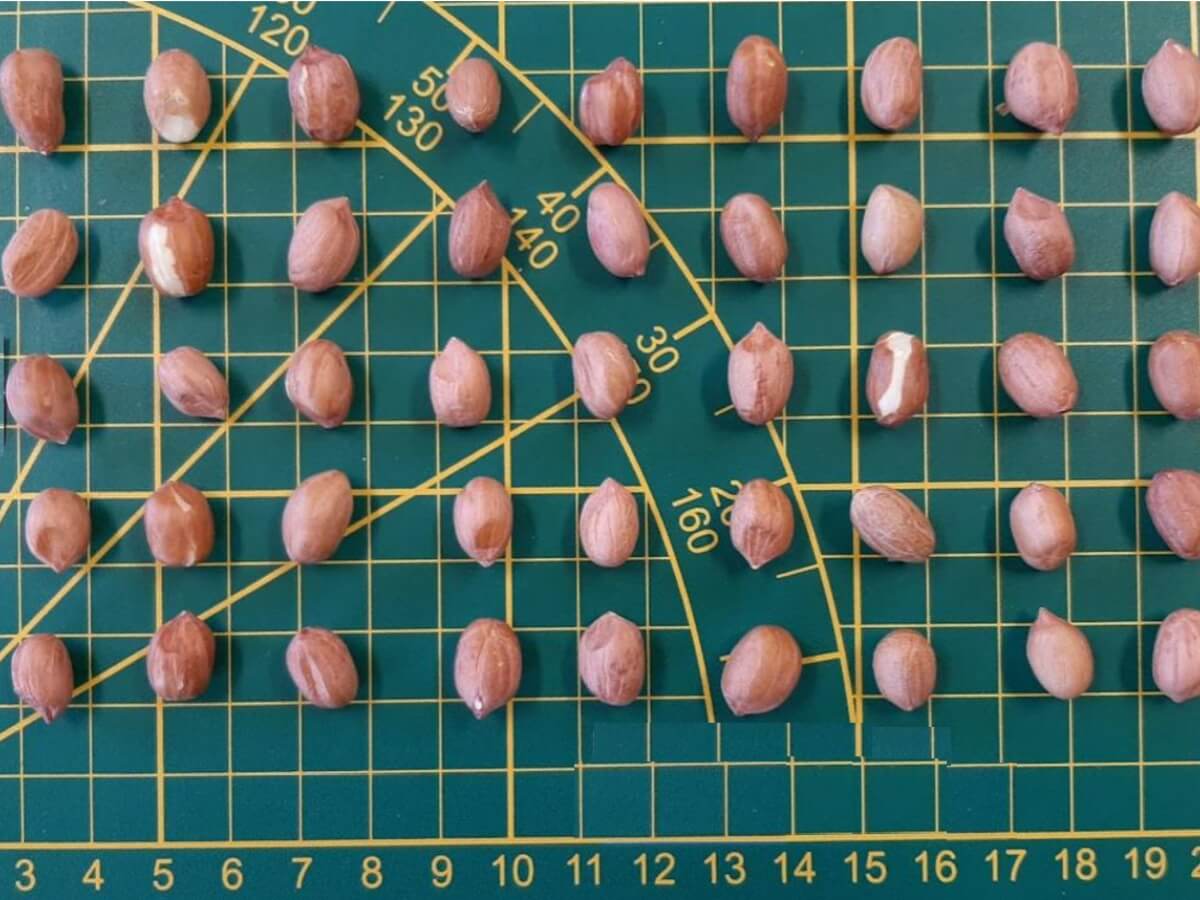

Image caption, describe the picture

Image caption, describe the picture

We set quality minimums to ensure that our peanut products are consistently well-balanced.

With ‘The Sift’, we’ve established the gold standard of peanut grading. This homegrown tool allows us to determine multiple peanut sizes within each grade and improve the quality of our processing.

We adapt the grading of our peanut supply to the needs of your products. Giving you freedom of choice, and making sure that every single peanut we procure finds the perfect home.

.jpg)

.jpg)

.jpg)

t.jpg)

.jpg)

.jpg)