It’s a peanut thing

From farming and processing to innovative products; we’re passionate about peanuts.

.png) We handle 20 origins of peanuts, from 87% of global origination sites

We handle 20 origins of peanuts, from 87% of global origination sites

.png) Engaging with 75% of direct global supply chain distribution

Engaging with 75% of direct global supply chain distribution

All from one simple ingredient

All from one simple ingredient

With thousands of customers worldwide, including in the challenging Japanese market, we set industry benchmarks by integrating every part of the peanut process.

We’re the world’s largest fully integrated peanut company, handling 6.5% of global peanut consumption.

We work globally with a local presence, but we work as one united team.

Our process is entirely touch-free, eradicating food safety risks such as salmonella and E. coli.

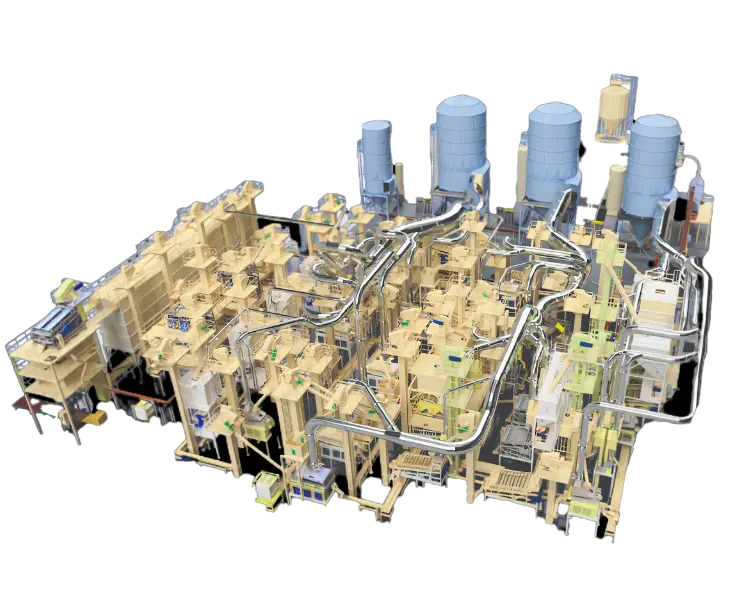

We use advanced technologies in our peanut processing: from biometric signatures to spectrometry and precision gravity separators.

.webp)

There’s no competition on quality

We work with world-class clients. So when it comes to quality we’re second to none.

Our in-depth knowledge of peanut science drives our commitment to building a stronger industry. And our proprietary quality system allows for zero tolerance when it comes to process defects.

.webp)

Work with us, and you’ll get more than just peanuts. You’ll get our standards too

Making ends meet

Our strength comes from our unbreakable will to improve. In our factories, our farms, and throughout our teams.

By distributing globally and operating at both ends of the industry, we are uniquely positioned to deliver sustainable growth, and remove friction throughout the supply chain.

Facilities Video

A rising tide lifts every boat

An integrated peanut industry works better for everyone. We’re determined that our efforts to turn norms on their head benefit all.

So that farmers, manufacturers, and consumers alike can reap the rewards of our work.

.jpg)

The future is important to us. By sharing our knowledge and connecting the dots, we can bring our vision of a passionate commitment to quality to life.

Peanut farming is changing, and we’re leading the charge.

By investing in aerofarms, IoT systems, satellite imagery and mechanisation, we’re ushering in the new age of the peanut.

Shared learning can only change things for the better.

We study other industries to find process enhancements that will improve outputs – and we share these insights with others.

As an end-to-end producer we work in origin sites all over the world.

And we’re committed to improving conditions and powering growth in those regions.

Agrocrops has a unique capability: working at a global scale, yet operating as one team.

Experience, tradition, and passion drive our peanut mission. And our knowledgeable, pragmatic leaders champion that approach.

Keep up to date with our latest initiatives.

.png)

Agrocrops, a company in the peanut processing industry, is entering the fast-moving consumer goods (FMCG) market with MyMani, a brand focused on peanut-based snacks and oils.

Enjoy the read: https://www.financialexpress.com/business/brandwagon-agrocrops-expands-into-fmcg-with-mymani-introduces-peanut-based-products-3780931/

.png)

Agrocrops hosted a four-day training on sustainable peanut farming practices in Veeracholan village, Virudhunagar district, from 6th to 9th December 2024. Led by Mr.Neelkanth Pandhare of the Rainforest Alliance, the programme welcomed 21 participants.

The training focused on key areas such as farm management, traceability systems, income-sharing models, social and environmental responsibility. Participants gained insights into sustainable farming techniques, including reducing chemical inputs, improving soil health, and adopting eco-friendly pest management. By aligning with Rainforest Alliance principles, the workshop empowered farmers to adopt sustainable agricultural practices, and meet the increasing demand for responsibly sourced peanuts.

.jpg)

We're thrilled to announce the launch of our 2023 Sustainability Report, which showcases our dedication to sustainable sourcing and carbon-smart peanut farming practices. Through this report, we share our journey of collaborating with over 25 Farmer Producer Organizations (FPOs) to responsibly source from 31,182 acres of farmland. A highlight of our efforts includes the use of biochar (charcoal from organic materials) to enhance soil health and sequester carbon, reducing our carbon footprint in every harvest. Committed to both environmental and economic resilience, we are setting new standards in the peanut industry by prioritizing eco-friendly farming practices that benefit our farming communities and the planet. This report embodies our ongoing vision for a sustainable, climate-resilient future in agriculture.

Check out our Report : https://issuu.com/agrocrops.com/docs/agrocrops_sdg_report_-2023

.png)

The journey of the Mani brand begins with a promise of peanut snack brand with global standards, tailored for the Indian consumers. CrunchMani launches in two exciting flavours: Garlic Crunch Delight and Spicy Chili Crunch, each offering a unique twist to satisfy consumers craving for crunch, nuts, and bold flavours. Agrocrops’ commitment to innovation in packaging, product quality, and taste makes CrunchMani the go-to snack choice for consumers across India.

.png)

Excited to share that OFI Magazine, a leading publication in the international oilseed industry, featured our High Oleic peanut! Thanks to Ranjith R visionary work for bringing Agrocrops is once again in the spotlight. Check out page 36 for more details !!

Enjoy the read: https://lnkd.in/grdadtnx

naturelle non détourée copy - Copy.jpg)

Agrocrops participated in the VAMP (Variétale pour l'Amélioration des Matières Premières) program in Madagascar, emphasising the importance of balanced fatty acids and protein quality in ready-to-use therapeutic foods (RUTF) for combating severe acute malnutrition. The event gathered 34 stakeholders from 13 countries, focusing on observing high oleic peanut trials, including varieties developed by Dr. Naveen Puppala, to identify RUTF-adapted varieties. Insights from trials conducted in seven countries, including Haiti, Guinea, Nigeria, and Ethiopia, were shared, contributing to a comprehensive understanding of RUTF-adapted varieties.

Agrocrops presentation highlighted support for local value chains to drive socio-economic impact and reduce the carbon footprint, underscoring the global commitment to addressing malnutrition effectively. Agrocrops practical approach to do commercial farming of the high oleic peanuts (HOPE) was well an recognised in the program. Agrocrops remain dedicated to advancing nutrition and sustainability for vulnerable communities.

Proudly harvested by.png)

Companies are propelled by exceptional talent and forward-thinking individuals. The achievement we celebrate today stands as a testament to this fact. Mr. Ranjith R, alongside Mr.VENKATESWARLU CHEVVA, played pivotal roles in realising this success. But our aspirations do not halt here; we aim to extend our reach globally.

Amidst numerous setbacks in our peanut farming. Our persistence and passion kept us going with HOPE (high oleic peanuts). We owe a debt of gratitude to the Farmers Producer Organizations (FPOs) and NGOs who believed in our vision and enabled us to make a meaningful impact, particularly among smallholder farmers, including women farmers.

We're thrilled to announce the launch of our new website –SpiceIndia.net a subsidiary of Agrocrops.

This platform is dedicated to providing an immersive experience in the world of spices starting with red dry chillies.

Explore the diverse range of premium Indian red dry chillies and more. From planting to manufacturing, we uphold a relentless pursuit of quality and sustainability. Your spices adventure begins here!

(1).jpg)

Agrocrops published its pioneering peanut-centric sustainability report, marking a pivotal moment in our 55-year journey from humble Indian roots to global prominence. The comprehensive report delves into our evolution, industry collaborations, certifications, and stakeholder engagement. Prioritizing sustainability, we align with UN SDGs and UNGC COP, reporting scope 1 & 2 emissions and outlining impactful initiatives.

This industry-first initiative sets an unparalleled standard, emphasizing our commitment to shaping the future of sustainability within the peanut sector.

Next year, our focus expands to Scope-3 emissions, a net-zero roadmap, and strategic collaborations for climate resilience, further solidifying Agrocrops' position as a trailblazer in sustainable business practices on a global scale.

Link to PDF

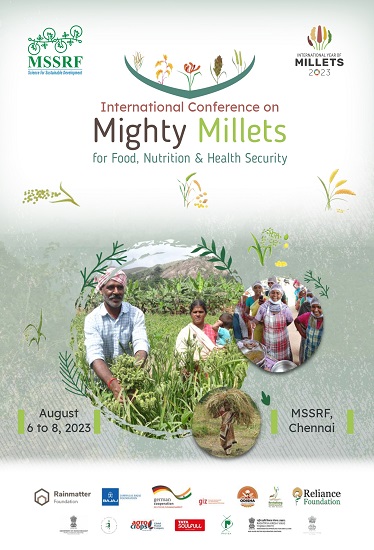

Agrocrops proudly supported the 'International Conference on Mighty Millets for Food, Nutrition, and Health Security' held in Chennai from August 6th to 8th, 2023. Partnering with the MS Swaminathan Research Foundation, the event highlighted the vital role of millets in sustainable food systems.

Agrocrops sponsored FPO stalls, featuring products from eco-friendly practices. Dignitaries, government representatives, and global researchers appreciated the initiative, reinforcing Agrocrops' commitment to fostering sustainable agriculture and promoting food security. The conference spotlighted the significance of millets in addressing global food challenges.

Agrocrops opened a new corporate office building in India (Chennai) to support its growth. Located in the central business district (CBD), now our human capital can grow manifold.

Agrocrops is constantly evolving and expanding in the peanut industry across all quarters.

Agrocrops is a proud sponsor of the IPF event each time it occurs. Our association with the American Peanut Council has lasted several years, and the event has grown in participation and diversity.

The 2023 IPF was unique, with two of our board of directors attending the conference to meet shellers and buyers across continents.

Ms Bhavani met the Singapore Ministry of Trade & Industry; Minister Gan Kim Yong was courteous in engaging Agrocrops to understand the support of the Singapore business ecosystem.

Agrocrops has a great vantage point by functioning its HO from Singapore.

Agrocrops has shipped 137,194 tons of peanuts from two major Indian ports, sourcing peanuts from over eight origins in India. This large quantity of peanuts exported by Agrocrops is more than 50% of what the entire US peanut industry ships, so it’s a big achievement.

Agrocrops has contributed to the storm-affected regions of Tamil Nadu, which have suffered from heavy rainfall generated by the annual north-east monsoon. We contributed drinking water, blankets, food, and medicine that amounted to a total of 2.3 million rupees, distributed evenly across the affected regions by all Agrocrops employees.

Despite enduring the hardship of the storm ourselves, we were able to help many people.

Agrocrops sponsors the IPF 2022, which is to be held in Hungary. It is the first physical event after the Covid-19 outbreak. The IPF is a biannual event conducted by the American Peanut Council; it is a global event that covers the entire spectrum of the peanut industry from snack producers, researchers, and traders to exporters, importers, and process technology managers.

.jpg)

Agrocrops has kicked off an information and knowledge sharing service called “Peanut Post”, specifically for stakeholders in the peanut industry.

Peanut Post is a monthly bulletin that talks about global peanut markets, best practices in peanut agriculture, peanut innovation, and sustainability in the peanut industry. Through the Peanut Post, Agrocrops wants to share its expertise far and wide with people in the industry.

Agrocrops has successfully registered the Pnutking trademark so we can offer our snack-producing clients a new benchmark for peanut wastage and safety standards. This move comes after careful research into technology and global standards for raw peanut ingredients such as USDA, Codex Alimentarius, and the EU and Japanese regulations.

Agrocrops is the first peanut company in India to get BRC A Grade certification for peanut processing. The factory is fitted with American technology and the production from the factory is sold as NON-HPS (HPS: hand-picked and selected).

Typically, Indian peanuts are sold as HPS grade, so Agrocrops has differentiated itself through process technology rooted in delivering efficiency and the highest food safety standards.

Agrocrops has procured land banks across the states of Andhra Pradesh, Karnataka, and Tamil Nadu to develop peanut factories in the greenbelts of these peanut-growing regions. Agrocrops will make these processing units captive and they will also be shared with the local farming and shelling community.

This will help them to reduce process waste and help to increase education and awareness of high-level technology for peanut processing. Plus, how to effectively handle post-harvest management.

These factories will focus on the sustainable development of the peanut industry, right in the peanut heartlands.

Agrocrops has invested US$5 million in bringing American peanut-processing technology and systems to India for the first time ever. Through the American peanut-processing system, Agrocrops can now process peanuts at 8-10 tons per hour, while processing peanuts on a “non-human touch” basis. This technique will ramp up food safety standards even further.

The American system will also help Agrocrops to reduce process waste, contributing to food security.

Agrocrops has signed an MoU with farmer producer organisations for larger-scale peanut farming. Through this MoU, Agrocrops and its agronomist team will offer farm inputs and POP (package of practices), and purchase the harvested peanut produce from the farmers at an agreed price and a premium – if the quality exceeds certain benchmarks.

Agrocrops’ FPO contracts are aimed at generating sustainable earnings for smallhold farmers.

Following the launch of an ad hoc introduction of the export SOP (standard operating procedure) that favours a few export players in the industry, Agrocrops filed a writ petition. We’re happy to say that the judge ruled in favour of our petition and our ability to export peanuts.

Agrocrops was the only peanut-exporting company contending the government’s abrupt introduction of policies, without giving a proper time frame in which to ensure compliance. So it’s a great win for us.

Agrocrops has invested in the research and development of an alternative peanut farming methodology. The investment in the polyhouse, aerofarming area of peanuts is aimed at achieving optimal use of water while improving yields many times over.

And the project aims to use the invaluable learnings to ramp up seed development and breeding.

Agrocrops has leased large land parcels in the southern states of India. The goal? To conduct large-scale commercial peanut farming as part of our upstream seed-to-shelf business strategy.

Land parcels of 80–250 acres are leased for a year for direct peanut farming. Now, we can easily showcase the best agricultural practices, while simultaneously working on our sustainability model for the Indian peanut agricultural industry.

Agrocrops has expanded its peanut processing capacity by installing an American-style shelling unit in Karnataka, India. Karnataka produces 5% of the Indian peanut harvest. It’s also renowned for producing one of the best-quality Spanish peanuts in India, with supplies of around eight months every year.

With this new resource, Agrocrops will be able to supply peanuts of the highest quality and lowest aflatoxin content, with an even higher level of production capacity.

Agrocrops has progressed its investment plan into American technology to process peanuts across India and beyond. We’ve secured funding from the US EXIM Bank via PNC Bank. The project is costing Agrocrops a total of US$4 million, which includes funding from an Indian bank and an American bank.

The project is set to give Agrocrops increased strength in the greenbelt of the peanut-growing regions, especially the smallhold farmers. The factory is spread across 17 acres of land, with a capacity of 10 tons per hour of shelling. We plan to share this resource with local shellers and farmers, who need the assistance of high-tech machines and our processing expertise.

Agrocrops has officially established its global head office in Singapore with a view to taking our peanut business global. The seed-to-shelf plan is global, handling peanuts from 20 different origins across upstream, midstream and downstream.

With the globalisation of the peanut business, Agrocrops can now take a major share of the US$32 billion industry.

During the Covid lockdowns, Agrocrops launched its first consumer brand as part of its downstream integration strategy in the peanut industry. But what is it? YES OIL is a cold-pressed peanut oil of a world-class standard but at an affordable price.

The brand has already been launched in the Tamil Nadu market, and is steadily progressing to spread nationally and internationally.

(1).jpg)

Agrocrops launched this exciting new initiative to build village ponds that will aid water conservancy for seven villages representing a total population of 1,500 people. This project set to cost two million rupees will be funded mostly by Agrocrops, with some donations from helpful associates.

The project has sustainability features such as rainwater harvesting that hold a world of promise for rural water accessibility.

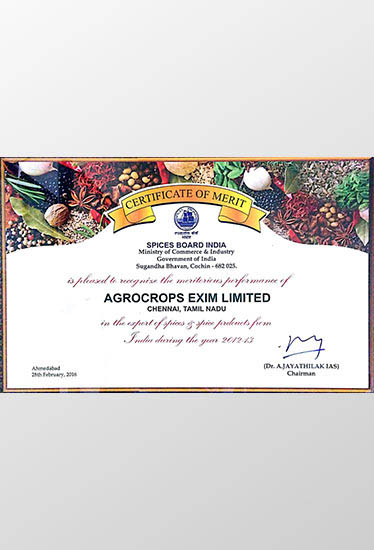

As one of the year’s top chilli exporters, Agrocrops has been awarded a prestigious accolade. The award was presented by the Spices Board of India under the Ministry of Commerce, and recognises us for having exported one of the largest quantities of chilli from India this year, at 8,100 tons.

We want to extend a big thank you to the team who worked so hard to achieve this accolade, dedicating their time and expertise across all the chilli-growing regions.

Agrocrops received the prestigious award of recognition from the Ministry of Commerce, as a Silver-level peanut exporter. The award recognises us for shipping the largest quantity of peanuts from India, with 73,880 tons this year.

Kudos to our dedicated team who worked hard across multiple ports in India to achieve this accolade. They expertly and efficiently handled the logistics of bringing the Indian peanut to the world and putting smiles on people’s faces.

.jpg)

Agrocrops was awarded the respected accolade of “Bronze Performer” by the Ministry of Commerce, recognising us as a Bronze-level peanut exporter. This award comes after we shipped 162,356 tons of peanuts this year from India.

A big congratulations and thanks to the team who have worked tirelessly across multiple ports in India to make this happen. It’s no small feat to handle the logistics of bringing the Indian peanut to market, after all.

We invited our best performers to receive the award on behalf of Agrocrops – Mr. Samsu Kani (Production Head) and Mr. Vasu Devan (Manager Documents).

.jpg)

Agrocrops has been named the number-one peanut exporter in India by the Ministry of Commerce. We performed the largest peanut shipment from India, with 74,838 tons of peanuts shipped this year.

We want to say a huge thanks to the Agrocrops team who have gone above and beyond to manage all origins of the Indian peanut to make this achievement possible. It’s not an easy thing to do, but they’ve managed it impressively.

We invited the team’s best performers to receive the award – Mr. Saravanan Lokasundaram (CEO) and Mr. Muthu Pandian (loyalist employee and all-rounder).

.jpg)

The rising export demand for chilli coupled with the success of Agrocrops’ strategic marketing has paved the way for a brand-new chilli processing plant. The chilli factory now employs 1,000-1,200 workers on a daily basis. The factory can carry out a range of tasks including grading, sorting, de-stemming, and colour sorting, and produces seeds, powder, and various cuts of chillies.

The factory also happily supports the education of all our permanent manual workers’ children.

.jpg)

Giving back to society has never merely been a CSR obligation for Agrocrops; it’s a way of life and an intrinsic part of our culture.

Where we see an opportunity to help, we take it and make it happen. And we particularly focus on the areas of food and education, where we will continue to make an impact wherever possible.